Clariant

Clariant develops sustainableadditives from rice bran by-products

Clariant's Licocare RBW Vita additives, made from rice bran by-products, enhance plastics processing while meeting strict Cradle to Cradle circular economy standards.

Clariant makes plastic environmentally friendly

Muttenz BL – The chemicals company Clariant is developing additives from by-products of rice bran oil production that are primarily used to help in plastics processing. In addition, these additives even comply with the strict circular economy principles of the Cradle to Cradle approach.

Among other things, the Licocare RBW Vita product line from Clariant facilitates quicker cycle times in the manufacturing of plastic products and a smoother,

more aesthetically pleasing surface for the end products. Moreover, these plastic additives also protect the environment. For this reason, the additives, which are produced on the basis of rice bran, have received recognition in the form of a Material Health Certificate Gold certification.

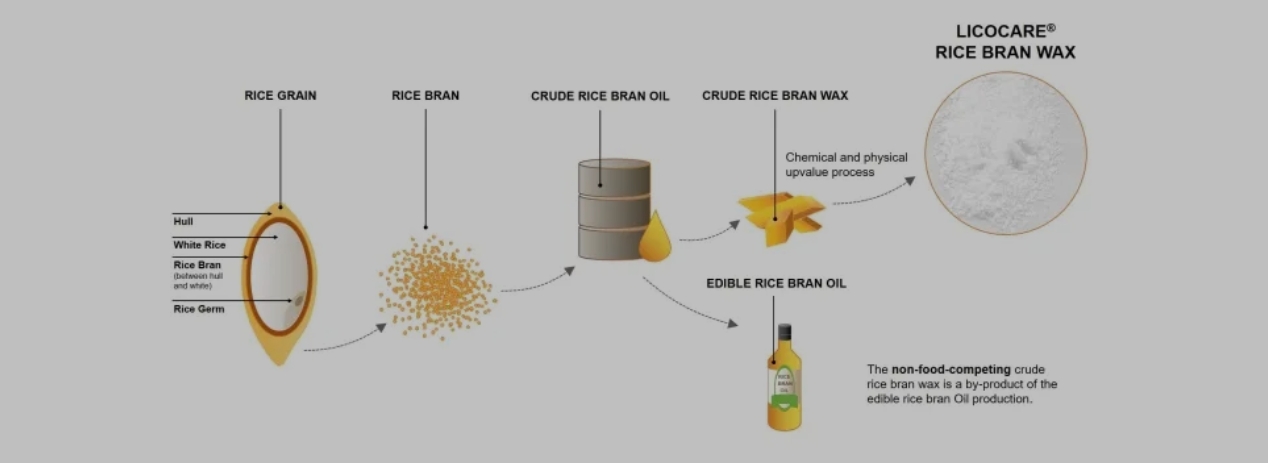

Clariant is developing the products for the Licocare RBW Vita range from bran wax obtained from rice. This

is a by-product of the production process behind rice

bran oil. Clariant refines this raw material both chemically and physically. The result is a high-performance additive for a wide range of plastics, for example polyamides, polyesters, polyolefins and biopolymers. The admixture of Licocare RBW Vita results in an improved polymer melt flow and makes demolding processes during injection molding easier. This presents plastics processors with advantages such as higher throughput and more complex design options. In addition, the surface of treated plastic products becomes smoother, something which is

often in demand for automotive and electronics

applications in particular.

In the development of Licocare RBW Vita, Clariant has been supported by EPEA Switzerland in its role as the accredited expert for Cradle to Cradle Certified

certifications. Together, they verified whether Licocare RBW Vita satisfies the relevant requirements. For example, EPEA Switzerland and Clariant examined whether the products in this range can safely enter the water cycle. Albin Kälin, CEO of EPEA Switzerland, praised Clariant as a role model following the successful process. He explained that the company has developed chemical solutions on the basis of

renewable resources, safe for both the water cycle and the rest of the environment.

For more information please go directly to the website of Clariant.